Optimal planning and operation of power-to-X systems

Poor economic feasibility has been identified as a key issue delaying the advancement of power-to-X systems.

Back

Introduction

Based on first-principle electrolysis models and advanced optimization algorithms, we hereby propose systematic solutions for the investment planning and operation management of power-to-X systems (e.g. power-to-hydrogen, power-to-methanol). The developed decision-making framework has been widely acknowledged by academia and used in the case of GreenLab Skive, Denmark. It can serve as a general tool to support the decision-makers of power-to-X systems.

Objectives

We are dedicated to:

- Proposing a high-accuracy dynamic electrolyser model towards the power-to-X system operation and planning optimization.

- Based on physical models and mathematical optimization, optimizing the operation of a power-to-X system (on-grid or off-grid) to reduce operational costs.

- Considering the modelling and operation issues at the planning stage to provide reliable and detailed investment suggestions.

Methology

The first-principle electrolysis model builds on:

- Electrochemical model

- Thermal model

- State transitional dynamic operational model

The operation optimization is conducted by:

- Mathematical formulation of the operation problem

- Uncertainty handling

- Solving resulting convex or non-convex optimization problem

The planning is based on:

- Identification of key economic metrics

- Establishment of a multi-layer decision-making framework, including the operational details

Data Analysis

Here, we provide an example from a power-to-methanol system. The system should satisfy the daily demand by producing on-site methanol through electrolytic hydrogen and CO2. It is connected to a utility grid and thus can participate in the electricity spot market. It is demonstrated that we significantly reduced operating costs by combining short-term prediction and optimized operational strategy.

In this case, we adopt detailed electrolyser and methanol synthesis plant models, ensuring the feasibility of the resulting operational strategies.

In this case, we adopt detailed electrolyser and methanol synthesis plant models, ensuring the feasibility of the resulting operational strategies.

Results

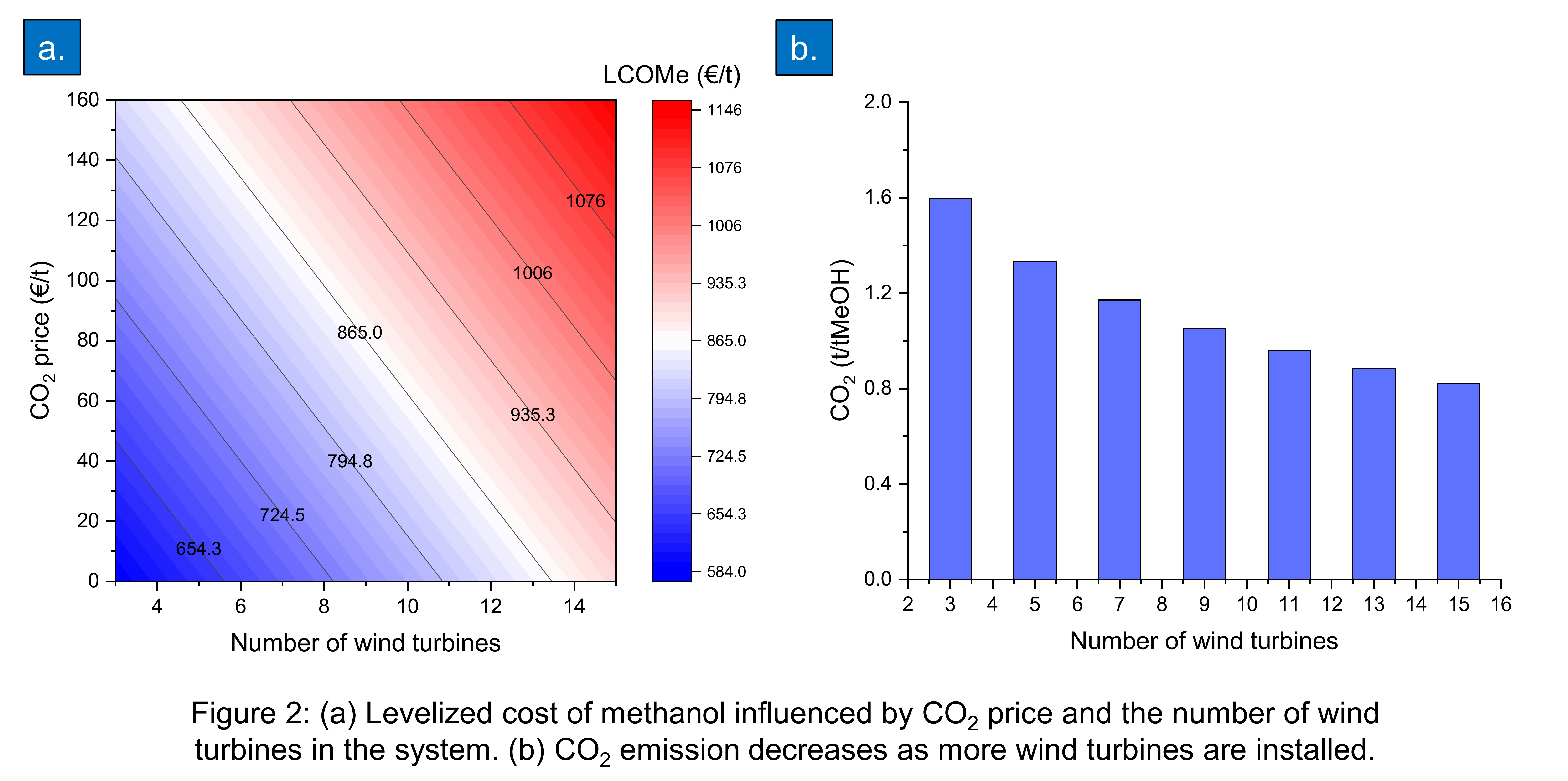

We further investigate the economic and sustainable performance of the system mentioned above. The levelized cost of methanol is calculated given different combinations of CO2 price and wind turbine numbers. In this specific case, more installing wind turbines lead to higher methanol cost due to a larger initial investment. Although operational costs would be reduced with more wind turbines, the increase in CAPEX dominates the cost change. Meanwhile, more costly CO2 raises methanol cost, as we expected.

CO2 emission has a negative relationship with wind turbine numbers. It is shown that more wind power makes the generated methanol cleaner, as more green hydrogen is produced from renewable power.[^1]

Conclusion

We have developed a systematic decision-making framework for the modelling, operation and planning of a power-to-X system. Such a framework can help the decision-making of the system investors, stakeholders, operators as well as policy makers.

References

[1] Y. Zheng, S. You, H. W. Bindner, and M. Münster, “Optimal day-ahead dispatch of an alkaline electrolyser system concerning thermal–electric properties and state-transitional dynamics” Applied Energy, vol. 307, p. 118091, 2022.

[2] Y. Zheng, S. You, H. W. Bindner, and M. Münster, “Incorporating optimal operation strategies into investment planning for wind/electrolyser system, ”CSEE Journal of Power and Energy Systems, vol. 8, no. 2, pp. 347–359, 2022.

[3] Y. Zheng, S. You, X. Li, H. W. Bindner, and M. Münster, “Data-driven robust optimization for optimal scheduling of power to methanol” Energy Conversion and Management, vol. 256, p. 115338, 2022.

Authors

Y. Zheng | S. You | X. Li | H. W. Bindner | M. Münster